-

-

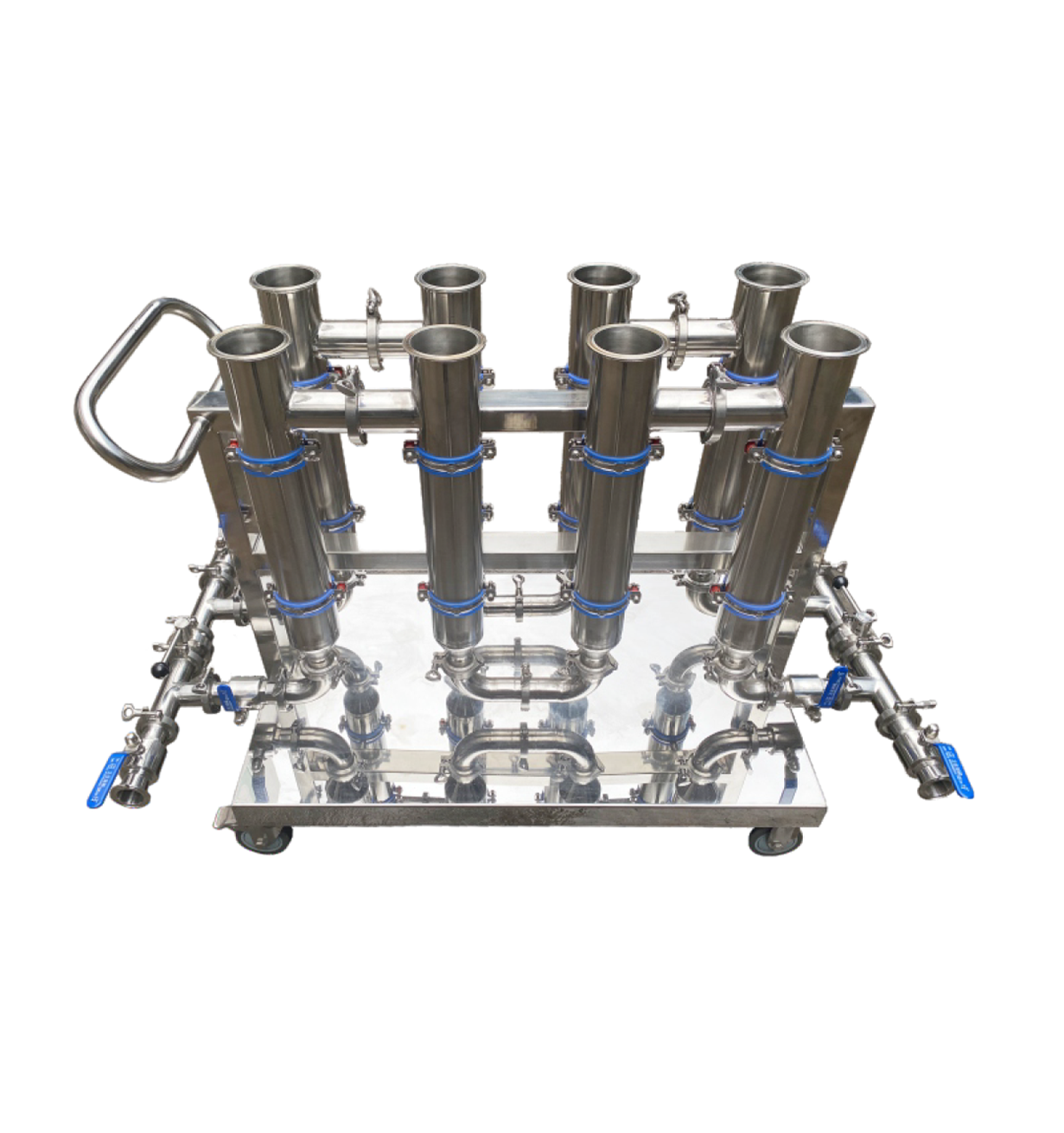

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Electromagnetic dry powder demagnetiser for lithium materials

Electromagnetic dry powder demagnetiser for lithium materials

-

Electromagnetic dry powder demagnetiser for lithium materials

Electromagnetic dry powder demagnetiser for lithium materials

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

Product

-

-

-

-

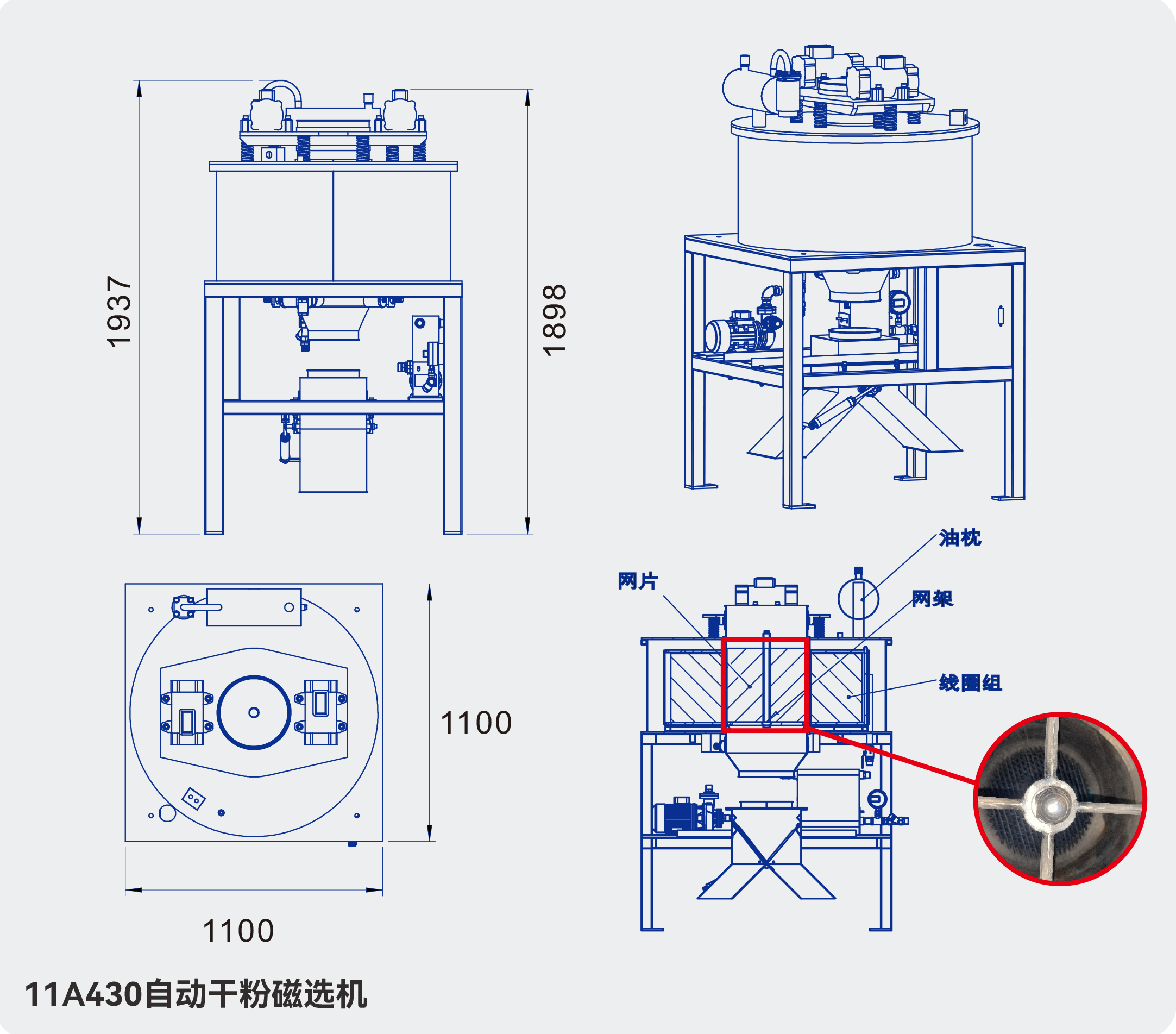

Electromagnetic dry powder demagnetiser for lithium materials

Key Word:

DESCRIPTION

Scope of application

The series of electromagnetic dry powder magnetic separators are suitable for separating fine magnetic impurities (e.g. iron powder) from dry powdery raw materials, and can cope with the more stringent requirements of positive and negative electrode materials, graphite, white carbon black and other powder materials. It is also widely used in the non-metallic mineral, plastic, ceramic, chemical, pharmaceutical and building material industries.

| Model | Power supply | Power | Working magnetic field | Capacity | Cooling methods | Mainframe weight | Dimensions |

| GY-ZF-7A300 | 380V/50HZ | 7KW | 8000Gs | 350-450kg/h | Oil-cooled | 920kg | 1100*1100*1937 |

| GY-ZF-11A430 | 380V/50HZ | 11KW | 10000Gs | 800-1000kg/h | Oil-cooled | 3200kg | 1710*1650*2115 |

| GY-ZF-25A430 | 380V/50HZ | 25KW | 15000Gs | 800-1000kg/h | Oil-cooled | 3200kg | 1710*1650*2115 |

Product Advantages

• Optimize structural design. Reduced operating energy consumption

• Intelligent control, smooth operation

• Unique piping design for smooth discharge and iron discharge without accumulation and blockage

• Can be customized according to customer requirements

Related Products

Get Product Quotes For Free

-

-

New materials series for lithium materials

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Electromagnetic dry powder demagnetiser for lithium materials

-

Electromagnetic dry powder demagnetiser for lithium materials

-

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

-

-

Foshan Guangyu Magnetoelectric Technology Co., Ltd

Tel:+86-13702989165

Web:www.fsgycd.com

E-mail:sales@fsgycd.com

Add:No. 46, South Side of Guidan Road, Luocun, Shishan Town, Nanhai District, Foshan City

Copyright © 2023 Foshan Guangyu Magnetoelectric Technology Co., Ltd