-

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Electromagnetic dry powder demagnetiser for lithium materials

Electromagnetic dry powder demagnetiser for lithium materials

-

Electromagnetic dry powder demagnetiser for lithium materials

Electromagnetic dry powder demagnetiser for lithium materials

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator

Product

-

-

-

-

Product

Contact

Tel:13702989165

Web:www.fsgycd.com

E-mail:sales@fsgycd.com

Add:No. 46, South Side of Guidan Road, Luocun, Shishan Town, Nanhai District, Foshan City

Lithium battery material special-purpose - electromagnetic slurry demagnetizer02

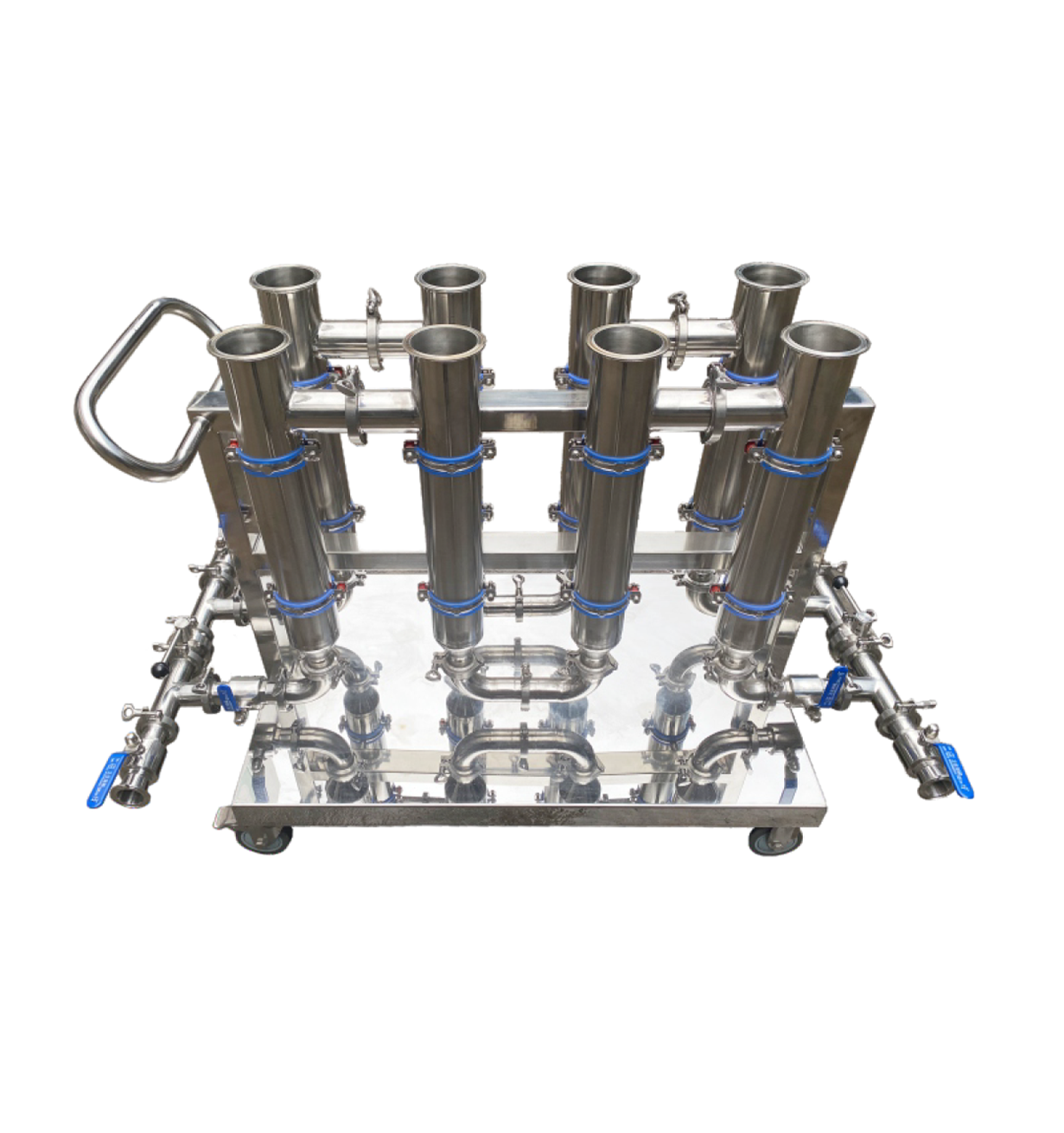

Lithium materials - Permanent magnet slurry separator03

Lithium materials - Permanent magnet slurry separator02

Lithium materials - Permanent magnet slurry separator

Lithium materials-Permanent magnetic dry powder iron separator02

Lithium materials-Permanent magnetic dry powder iron separator

-

-

New materials series for lithium materials

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Lithium battery material special-purpose - electromagnetic slurry demagnetizer

-

Electromagnetic dry powder demagnetiser for lithium materials

-

Electromagnetic dry powder demagnetiser for lithium materials

-

Lithium materials-Permanent magnetic dry powder iron separator

-

Lithium materials-Permanent magnetic dry powder iron separator

-

-

Foshan Guangyu Magnetoelectric Technology Co., Ltd

Tel:+86-13702989165

Web:www.fsgycd.com

E-mail:sales@fsgycd.com

Add:No. 46, South Side of Guidan Road, Luocun, Shishan Town, Nanhai District, Foshan City

Copyright © 2023 Foshan Guangyu Magnetoelectric Technology Co., Ltd