Guangyu Magnetoelectronic

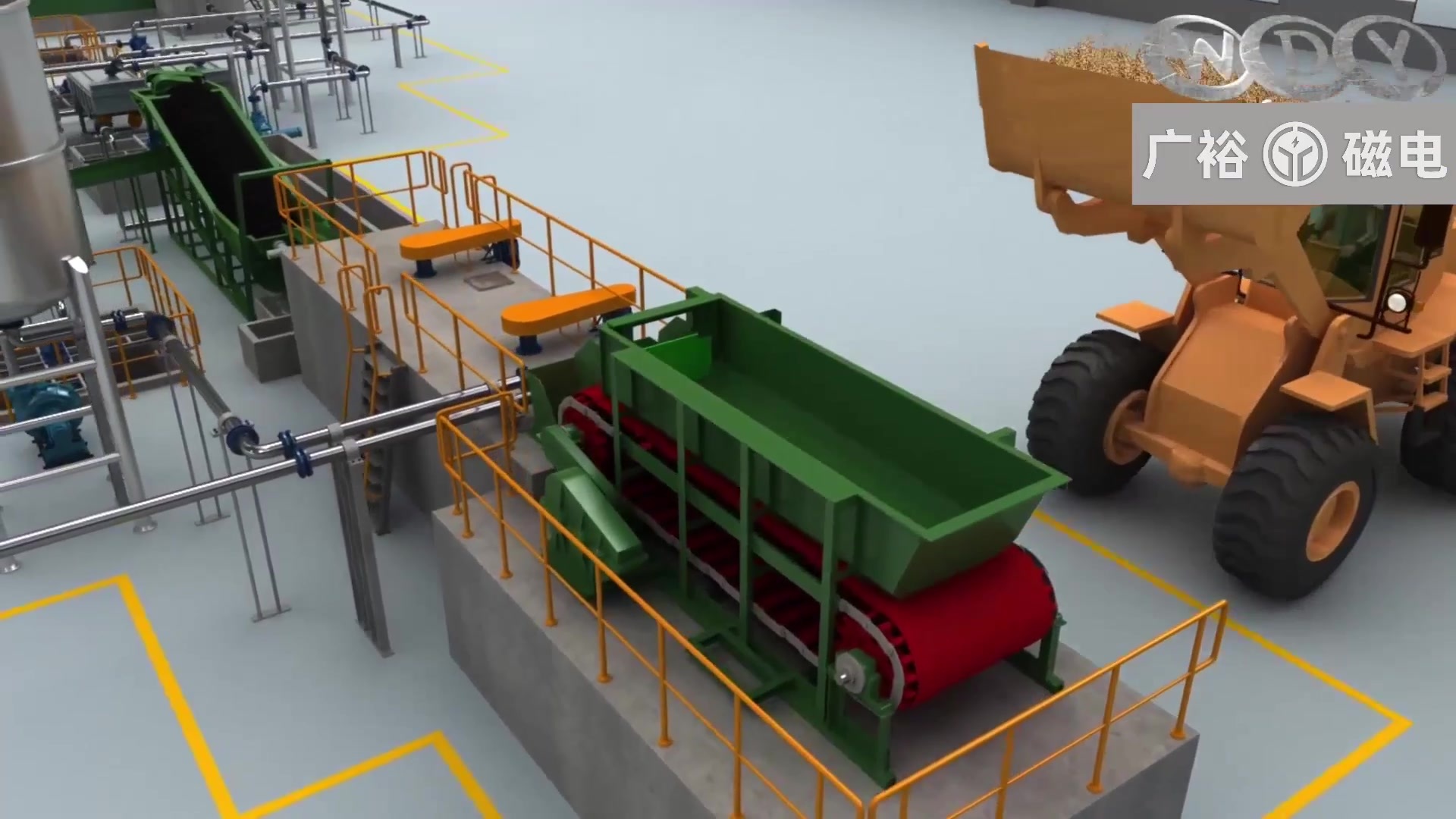

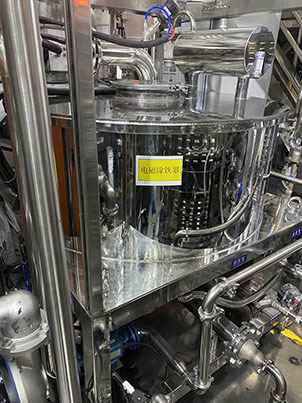

Foshan Guangyu Magnetoelectronic Technology Co., Ltd. is a professional manufacturer of magnetic separation equipment that integrates scientific research and development, engineering design, production line installation, and debugging services. Its main products include: various specifications of high gradient electromagnetic slurry machines, powder magnetic separators, permanent magnetic separators, electromagnetic vertical ring machines and magnetic plates, iron removal boxes, magnetic rods, etc. Widely used in industries such as mining, ceramics, electricity, building materials, glass, environmental protection, rubber, plastic, medicine, food, positive and negative electrode materials, etc., it has developed a strong foothold in the Pearl River Delta, deeply cultivated the domestic market, and exported to countries and regions such as Vietnam, India, Iran, Egypt, Malaysia, etc.

HOT PRODUCTS

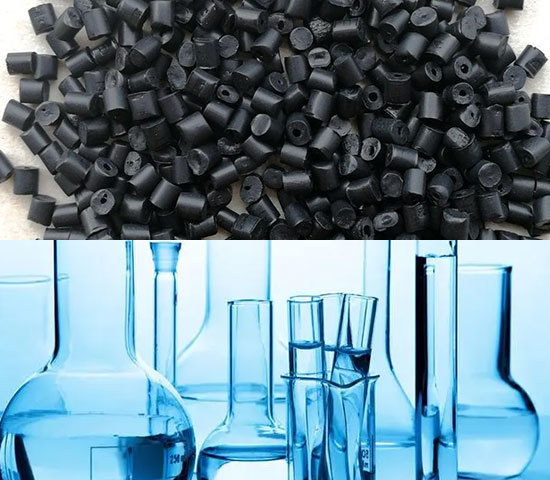

Lithium materials-Permanent magnetic dry powder iron separator

Lithium materials-Permanent magnetic dry powder iron separator02

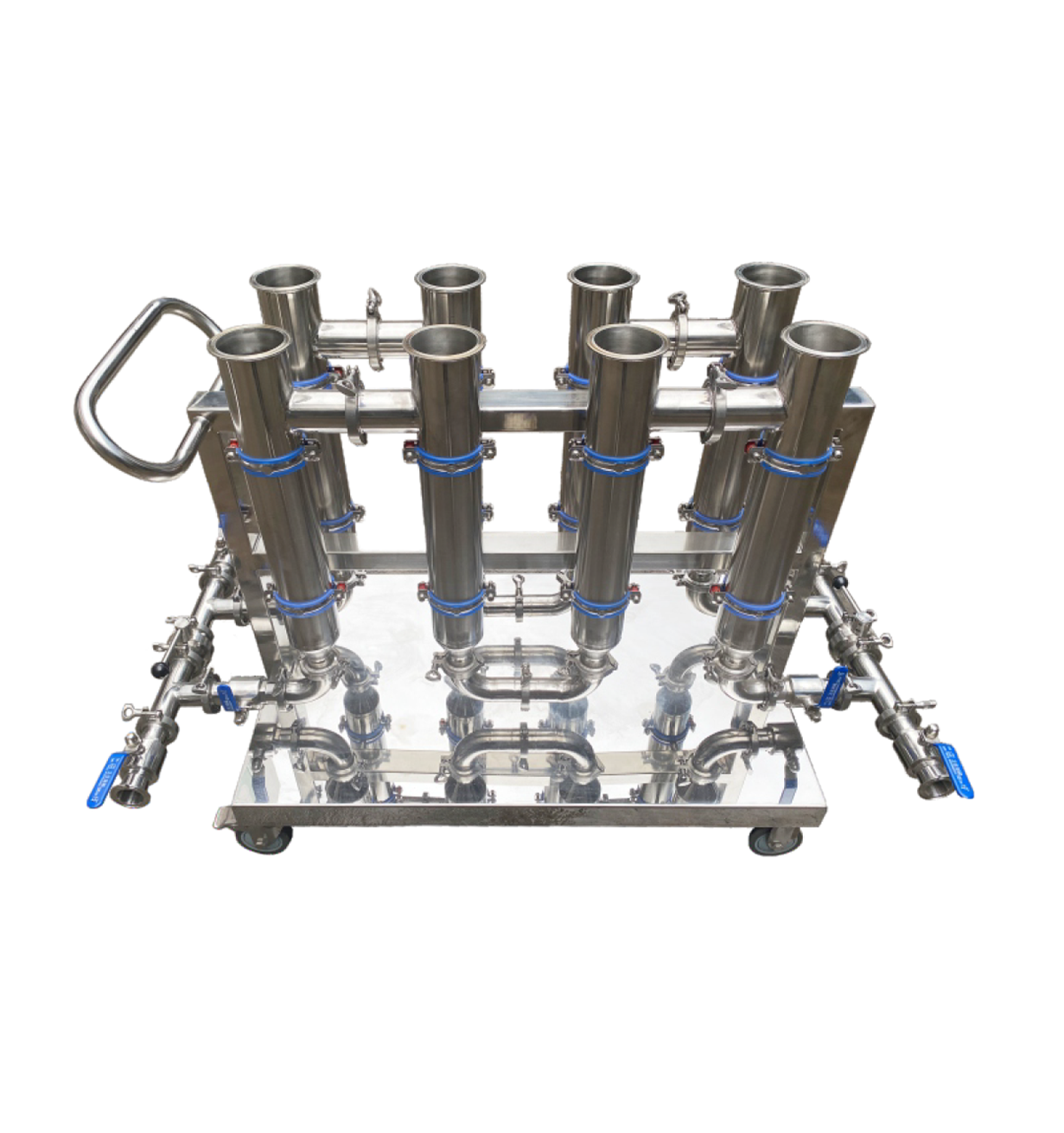

Lithium materials - Permanent magnet slurry separator

Lithium materials - Permanent magnet slurry separator02

TECHNICAL EXPERTS

APPLICATION

ADVANCED TECHNOLOGY

Experience

Technology

Full Service

Experience

Always adhering to the direction of professional development, experienced and professional manufacturer of magnetic separation equipment research and development

Technology

Iron and magnetic removal technology maintains advanced domestic level and continues to make progress

Full Service

We always believe that we will do better by providing excellent quality and perfect service

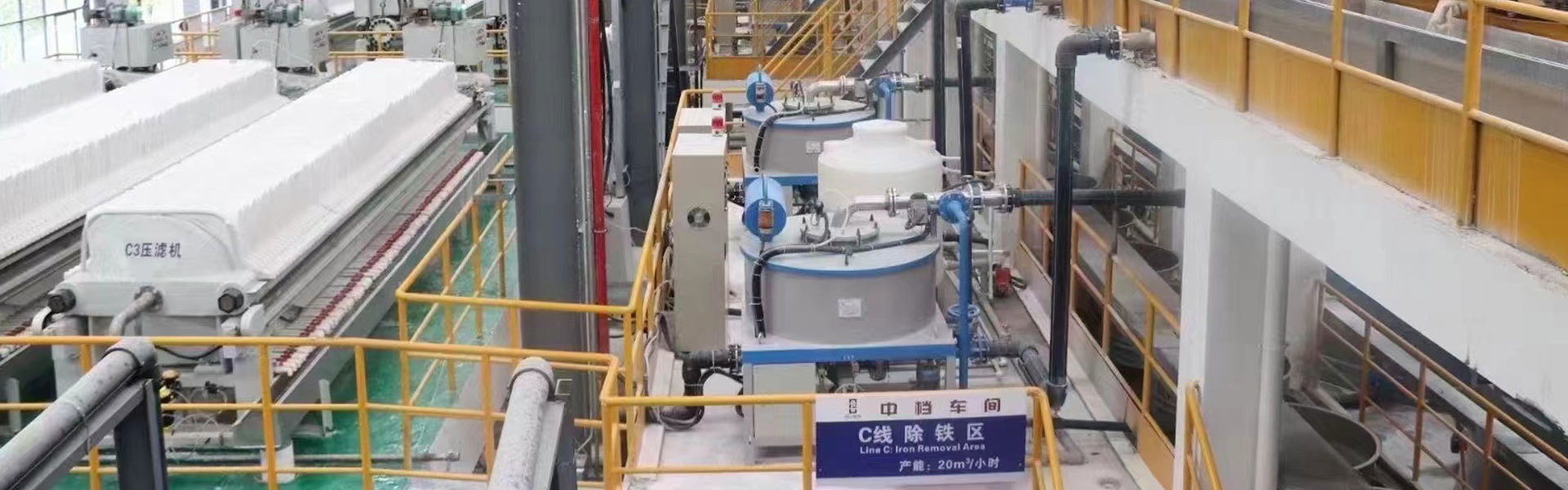

ENGINEERING

COOPERATIVE PARTNERS

NEWS

The difference between electromagnetic separators and permanent magnet separators.

2025-01-07

Regarding the selection direction of electromagnetic separators and permanent magnet iron removers.

Iron removal effect of iron separators

2023-04-27

Correct installation and hanging will have a great impact on the effectiveness of the iron separator. In practice they should be used and maintained correctly in order to achieve the best possible iron removal effect.

The direction of development of the iron remover

2023-04-27

Better materials are applied to optimize the magnetic field strength of the iron remover with an increasing gradient.